3D printing: where does it fit in industry?

How does 3D printing fit into the industrial sector? Focus on its advantages and technological potential.

In recent years, new technologies have revolutionized the world ofindustry. 3D printing is one of them. With its many possibilities, the copying machine of Industry 5.0 has taken on a new role in the design and production of objects. How does 3D printing work, and what impact will it have on the industrial sector?

What is 3D printing?

Since the advent of the fourth industrial revolution, major changes have taken place, notably with the arrival of new technologies. 3D printing is one of these. Otherwise known as " additive manufacturing ", this innovation makes it possible to copy real objects. This is made possible by high flexibility, precision and speed.

How does this innovative technology work?

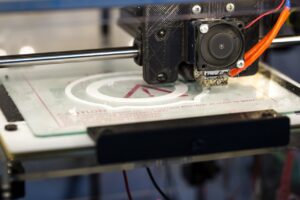

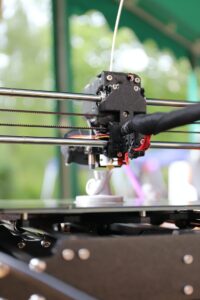

3D printing works by transforming a digital model into a three-dimensional physical object. The process is actually quite simple: several layers of thermoplastics are superimposed to form an object that can then be polished and painted. No additional tools, such as molds, are required to operate the printer. The only element required is an STL or OBJ digital file, which is integrated into the printer software by a professional.

The 3D parts we manufacture are carefully crafted to function optimally and retain their physical properties. They perform the same functions as the original parts.

Why use 3D printing in industry?

3D printing has found a place of choice in industry: it reduces production costs and enables the creation of complex parts.

It contributes to the creation of customized products that meet customer needs. In the automotive industry, for example, manufacturers are able to create parts that are perfectly adapted to a specific vehicle. The company can then promote this customization advantage to its customers. This is a convincing and useful new argument for sales agents.

3D printing also makes it easy to produce prototypes. Companies can turn ideas into objects and test them, without wasting time and money.

The machine is also useful for considerably reducing storage costs. It eliminates the need for physical storage of parts, and reduces production time. Manufacturing costs are also reduced, and the profitability of manufacturing processes boosted. It is no longer necessary, for example, to make welded assemblies, or to purchase and transport components from elsewhere.

The 3D printer promotes intelligent production by facilitating the exchange of information between production systems. This technology also simplifies maintenance by rapidly creating spare parts for certain machines. It ensures that production equipment operates as efficiently as possible.

Like Industry 5.0, it requires perfect collaboration between man and machine. Workers must be able to program and manage industrial machinery. This is giving rise to new professions.

While 3D printers offer the opportunity to better respond to market needs, they also contribute to respecting the environment. It consumes fewer resources and produces less waste.

In which sectors is 3D printing the most popular?

3D printing is gradually making its way into many sectors.

In the automotive industry, technology is helping to cut costs and save time in the manufacture of certain items. Companies now design certain parts themselves, more efficiently. This minimizes costs and promotes resilience.

In the aeronautics industry, 3D technology makes it possible to produce lighter parts and simplify production processes, while complying with current standards.

This revolutionary tool is also used in the medical field. It enables the production of a wide variety of complex parts, particularly in the dental sector.

It is particularly valuable in the research and development sector for creating and modifying prototypes.

A future for 3D printing

3D printing has a bright future in industry, with more and more techniques and materials available. Indeed, 3D printing is becoming the preferred manufacturing method in many sectors, thanks to its practicality, precision and design speeds. This cutting-edge technology is a considerable asset for industrial innovation. It has become necessary to meet new needs, adapt to markets and differentiate to remain competitive.

Our company AMEG Group integrates these technological innovations at the heart of numerous projects. Contact us to find out more.